SGTR «КАМА» – New generation of Station GTR

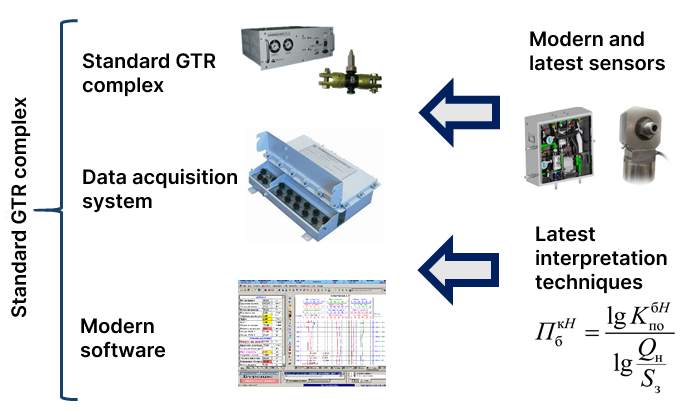

Since 2010, JSC AMT LLC and SPE GE LOOCH LLC began cooperative development of a new generation geological and technological research station (GTR) using AMT's competencies in the field of geological and technical research, the experience of creating complex geophysical equipment of the LOOCH enterprise and with the methodological support of an academician of the Russian Academy of Natural Sciences , Doctor of Technical Sciences E. E. Lukyanova.

SGTR «КАМА» – is

improved metrological and operational characteristics and quality of a standard set of process sensors;

new measuring systems and sensors;

a set of tools to protect data from unauthorized changes, losses in emergency situations and guarantee their integrity;

new software methods for the operational interpretation of geological survey data;

integration with Geophysical Well Surveys methods (autonomous logging, logging while drilling and development).

Modular architecture of modern GTR stations

Monitoring drilling parameters

Information support for drilling crew personnel

Control of more than 40 measured and calculated drilling parameters

Complete examination of rock material (sludge, core)

Recognition of complications and emergency situations at the initial stage, including gas and oil shows during drilling, PO and cementing

Real-time well monitoring information system provides real-time transmission of:

- geological and technological information;

- results of solving technological problems;

- results of solving geological problems;

- technical and economic indicators;

- targeted SMS notifications.

- geological and technological information;

- results of solving technological problems;

- results of solving geological problems;

- technical and economic indicators;

- targeted SMS notifications.

High-precision measurements of process parameters

High Resolution Traveling Block Position Meter

High precision weight meter

High-precision measurements of drilling fluid parameters

Density, level, temperature and resistance meters for drilling fluid

Determination of the volumetric gas content of drilling fluid using the compression method and acoustic method

Full suite of fluid logging

High precision electromagnetic outlet flow metering.

Determination of manifestations, absorption of any scale; accurate identification of porous and fractured reservoirs, superreservoirs; absorptions and manifestations under conditions of abnormal reservoir pressures, etc.

Determination of manifestations, absorption of any scale; accurate identification of porous and fractured reservoirs, superreservoirs; absorptions and manifestations under conditions of abnormal reservoir pressures, etc.

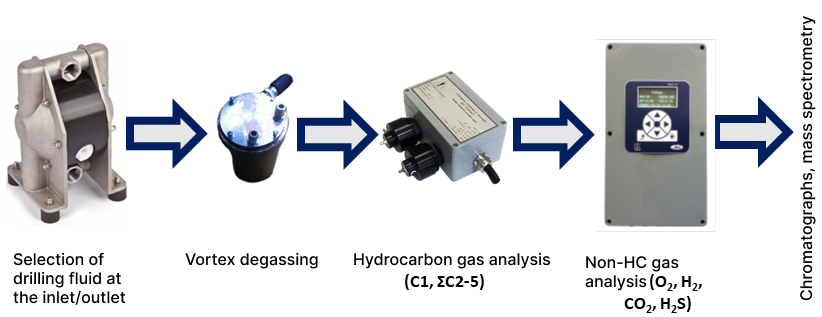

Next generation gas logging

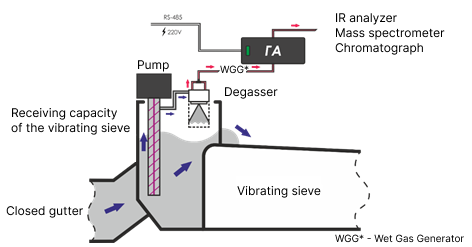

Degassing and gas analysis system at the drilling rig.

Gas analysis equipment.

Complete examination of rock material (sludge, core)

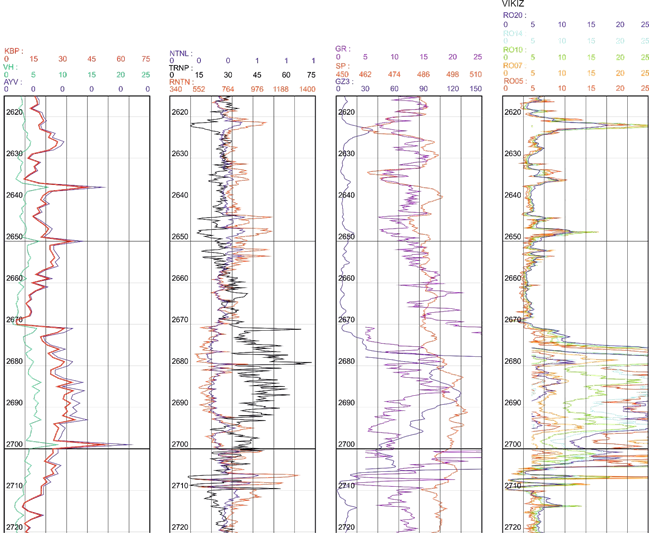

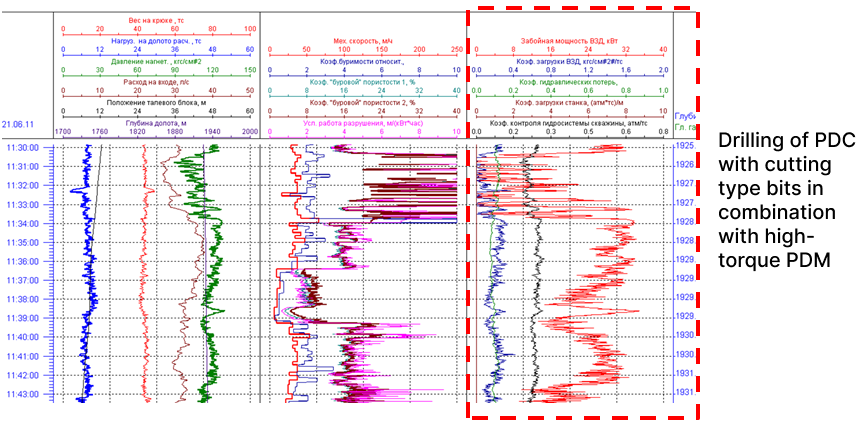

New methods for interpreting GTR data

Gas log logging and interpretation.

Determination of drilling porosity, drillability coefficients, geomechanical properties.

Identification of zones of Anomalously High Reservoir and/or Pore Pressure

Implementation of a complex of automated processing, interpretation and presentation of information that increases the efficiency of the station.

When identifying reservoir layers, instead of mechanical drilling speed, it is proposed to use the energy intensity parameter of rocks as a petrophysical indicator of the drilling process.

Integration GIS-GTR, LWD-GTR

An example of the integration of GIS and GTR in the context of Western Siberia: